Create parametric 3D fusion reactor CAD models

Paramak

J. Shimwell, J. Billingsley, R Delaporte-Mathurin, D. Morbey, M. Bluteau, P. Shriwise, A. Davis

This work was funded by the RCUK Energy Programme

[Grant number EP/P012450/1]

Motivation - automation

Diagram / sketch / idea

Manual CAD model creation via GUI

CAD model geometry created

Manual CAD model cleaning via GUI

Analysis

Motivation - speed at scale

Model complexity

CSG models

Lines of code

CAD Shapes

CAD Components

Decompose existing models

Example CAD model based on EU-DEMO

Method

12 Shapes

37

Components

9

Reactors

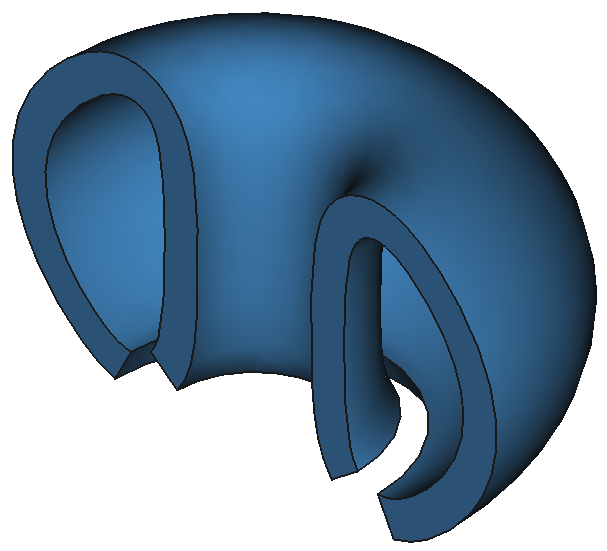

Base parametric Shapes()

- Shapes require the user to provide points / coordinates to make a 3D geometry.

- A rotate, extrude or sweep operation is applied to the points

- Boolean operations such as cut, union, intersection are supported

- Repeating patterns around an axis are supported

Components from Shapes

import paramak

height = 700

blanket_rear = 400

blanket_front = 300

blanket_mid_point = 350

blanket = paramak.RotateMixedShape(

rotation_angle=180,

points=[

(blanket_rear, height / 2.0, "straight"),

(blanket_rear, -height / 2.0, "straight"),

(blanket_front, -height / 2.0, "spline"),

(blanket_mid_point, 0, "spline"),

(blanket_front, height / 2.0, "straight"),

]

)

blanket.export_stp('"blanket.stp")

import paramak

blanket = paramak.RotateMixedShape(

rotation_angle=180,

points=[

(538, 305, "straight"),

(538, -305, "straight"),

(322, -305, "spline"),

(470, 0, "spline"),

(322, 305, "straight"),

]

)

blanket.export_stp("blanket.stp")

CAD from points

CAD from parameters

Simple Parametric Compents

All instances of Shape classes with encoded design rules for generating the points needed

More complex Components

All instances of Shape classes with encoded design rules for generating the points needed

Parametric Components()

Parameters CAD geometry DAGMC h5m OpenMC simulation

Example parametric Reactors

import paramak

my_reactor = paramak.BallReactor(

inner_bore_radial_thickness=10,

inboard_tf_leg_radial_thickness=30,

center_column_shield_radial_thickness=60,

divertor_radial_thickness=150,

inner_plasma_gap_radial_thickness=30,

plasma_radial_thickness=300,

outer_plasma_gap_radial_thickness=30,

firstwall_radial_thickness=30,

blanket_radial_thickness=50,

blanket_rear_wall_radial_thickness=30,

elongation=2,

triangularity=0.55,

number_of_tf_coils=16,

rotation_angle=180,

pf_coil_radial_thicknesses=[50, 50, 50, 50],

pf_coil_vertical_thicknesses=[50, 50, 50, 50],

pf_coil_to_rear_blanket_radial_gap=50,

pf_coil_to_tf_coil_radial_gap=50,

outboard_tf_coil_radial_thickness=100,

outboard_tf_coil_poloidal_thickness=50

)import paramak

my_reactor = paramak.SubmersionTokamak(

inner_bore_radial_thickness=30,

inboard_tf_leg_radial_thickness=30,

center_column_shield_radial_thickness=30,

divertor_radial_thickness=80,

inner_plasma_gap_radial_thickness=50,

plasma_radial_thickness=200,

outer_plasma_gap_radial_thickness=50,

firstwall_radial_thickness=30,

blanket_rear_wall_radial_thickness=30,

number_of_tf_coils=16,

rotation_angle=180,

support_radial_thickness=90,

inboard_blanket_radial_thickness=30,

outboard_blanket_radial_thickness=30,

elongation=2.00,

triangularity=0.50,

pf_coil_radial_thicknesses=[30, 30, 30, 30],

pf_coil_vertical_thicknesses=[30, 30, 30, 30],

pf_coil_to_tf_coil_radial_gap=50,

outboard_tf_coil_radial_thickness=30,

outboard_tf_coil_poloidal_thickness=30,

tf_coil_to_rear_blanket_radial_gap=20,

)

Decompose existing models

Image source Overview of the SPARC tokamak. Journal of Plasma Physics, 86(5), 865860502. doi:10.1017/S0022377820001257

Progress

Rough estimate of how we have built up the number of parametric shapes, parametric components and parametric reactors over time.

12

33

6

Neutronics Support

Geometry output formats:

- stp

- stl

- h5m

- vtk

Automatic conversion of geometry into DAGMC based neutronics geometry

(h5m file)

import paramak

# # makes the 3d geometry from input parameters

my_reactor = paramak.BallReactor(

inner_bore_radial_thickness=50,

inboard_tf_leg_radial_thickness=200,

center_column_shield_radial_thickness=50,

divertor_radial_thickness=50,

inner_plasma_gap_radial_thickness=50,

plasma_radial_thickness=100,

outer_plasma_gap_radial_thickness=50,

firstwall_radial_thickness=1,

blanket_radial_thickness=100,

blanket_rear_wall_radial_thickness=10,

elongation=2,

triangularity=0.55,

number_of_tf_coils=16,

rotation_angle=360,

)

my_reactor.export_stp()

my_reactor.export_stl()

my_reactor.export_h5m(method='pymoab')

my_reactor.export_h5m(method='trelis')

my_reactor.export_vtk()

Neutronics Support

Addition of:

- materials,

- tallies,

- source

to combine with the neutronics geometry to make a neutronics model

import paramak

# # makes the 3d geometry from input parameters

my_reactor = paramak.BallReactor(

inner_bore_radial_thickness=50,

inboard_tf_leg_radial_thickness=200,

center_column_shield_radial_thickness=50,

divertor_radial_thickness=50,

inner_plasma_gap_radial_thickness=50,

plasma_radial_thickness=100,

outer_plasma_gap_radial_thickness=50,

firstwall_radial_thickness=1,

blanket_radial_thickness=100,

blanket_rear_wall_radial_thickness=10,

elongation=2,

triangularity=0.55,

number_of_tf_coils=16,

rotation_angle=360,

)

# makes the neutronics model from the geometry and materials

neutronics_model = paramak.NeutronicsModel(

geometry=my_reactor,

materials={

'inboard_tf_coils_mat': 'eurofer',

'center_column_shield_mat': 'eurofer',

'divertor_mat': 'eurofer',

'firstwall_mat': 'eurofer',

'blanket_rear_wall_mat': 'eurofer',

'blanket_mat': 'Li4SiO4'},

cell_tallies=['TBR', 'heating'],

simulation_batches=5,

simulation_particles_per_batch=1e4,

)

neutronics_model.simulate()

Use cases - parameter studies

Carrying out a multi dimensional parameter study can be achieved with relatively low user effort

Software practices employed

Automated static code analysis with code-inspector.com

Automated docker build and distribution to dockerhub

Testing with Circle CI and Github Actions

Code coverage

Automated PyPi updating

Online Documentation

Summary

Automated geometry can help speed up the current

design process for pre-conceptual design

Documentation

https://paramak.readthedocs.io

Source code

https://github.com/ukaea/paramak

Package Distribution

https://pypi.org/project/paramak/

Environment Distribution

Software review

RSE review prior to going opensource (M. Bluteau)

Provision of review document

PullRequest.com review after v0.2 release

Agile (working progress)

- Regular meet ups between the core developers

- Project boards to track progress

- Discussion with customers, define the product

- Deliver MVP and then iterate.

Automated - software review

www.code-inspector.com

Preparing for compute

OpenMC: A state-of-the-art Monte Carlo code for research and development

Dimensional reduction removes some variables but the number of simulations require to explore the parameter space is stilll quite large.

Speeding up the neutronics workflow